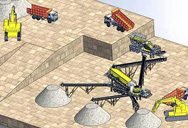

gravity separation plant recovery of minerals

Gravity Separation - SGS

To recover malleable and/or friable coarse heavy minerals from grinding circuit circulating loads. Such minerals are otherwise hard to recover after regrinding To pre-concentrate heavy minerals to minimize downstream processing costs To concentrate heavy

Charlar en Línea

How Gravity Separation Works to Recover Metals and

How To Implement Gravity Separation To start recovering gold and other precious metals using the principles of gravity separation, contact the

Charlar en Línea

(PDF) Minerals Recovery and Processing - ResearchGate

2005.12.2 Minerals separation or concentration methods may include ore sorting, gravity concentration, magnetic or electrostatic

Charlar en Línea

Enhanced Gravity Recovery of Base Metal and Industrial Minerals

Gravity concentration is one of the oldest and most cost effective metal and/or mineral recovery systems, ranging from the classic hand panning of alluvial gold, through to the large scale production of a wide range of metals and minerals, including gold, silver,

Charlar en Línea

Gravity Separation - ScienceDirect

2016.1.1 The principle employed in gravity separation goes back further in time to the formation and weathering of the rocks and the releasing of the minerals they contain and the transport of the mineral grains by heavy rains.

Charlar en Línea

Size recovery curves of minerals in industrial spirals for

2014.10.15 As in any gravity concentrators the separation of minerals in a spiral is based on particle size and specific gravity. The size recovery curves of minerals in mineral processing equipment provide an efficient way to analyse the operation of spiral

Charlar en Línea

Gravity Concentration In Modern Mineral Processing

Gravity Concentration In Modern Mineral Processing D. J. Ottley Chapter 321 Accesses 2 Citations Part of the NATO ASI Series book series (NSSE,volume 117) Abstract A review is presented of the range and type of gravity separation processes available and

Charlar en Línea

ULTRA-FINE GRAVITY SEPARATION OF RARE EARTH MINERALS

early 2000’s, have recently enabled new avenues for gravity separation at comparatively finer particle sizes than previously considered practical. In regards to the recovery of rare earth minerals, the use of UF Falcons coupled with parallel advancements in flotation

Charlar en Línea

Minerals Free Full-Text Concentration and Recovery

2020.11.30 When a magnetic separation and gravity separation of the non-magnetic fraction was made, the recovery rate of magnetite was 85.09%, ilmenite 86.96%, monazite 91.06%, and zircon 90.82%. This

Charlar en Línea

- trituradora de granito piezas de repuesto

- molino de bolas de aluminio para el dibujo de mineria de oro

- vertical de molienda molino de rodillos

- Trituradora Ramas Anúncios

- Sayaji Indore fabricante de trituradora de piedra

- trituradora de asfalto de hormigon

- Distribuidor En Piedra

- partes de la mandíbula trituradora de carbón de rusia

- basalto piedra de trituración de la planta

- trituradora de mineral de hierro en venta maquinaria trituradora de plasticos1

- móvil trituradora de piedra precio de la máquina

- circón completa de equipos de proceso

- molino de bolas para la producción de oro

- kraft trituradoras de cono lubriion

- molinos de bolas en chihuahua cd juarez